Rubber & Plastic Extrusion Equipment

- Rubber Extrusion Equipment

- Plastic Extrusion Equipment

Rubber Extrusion Equipment

Manufacturing and processing equipment list

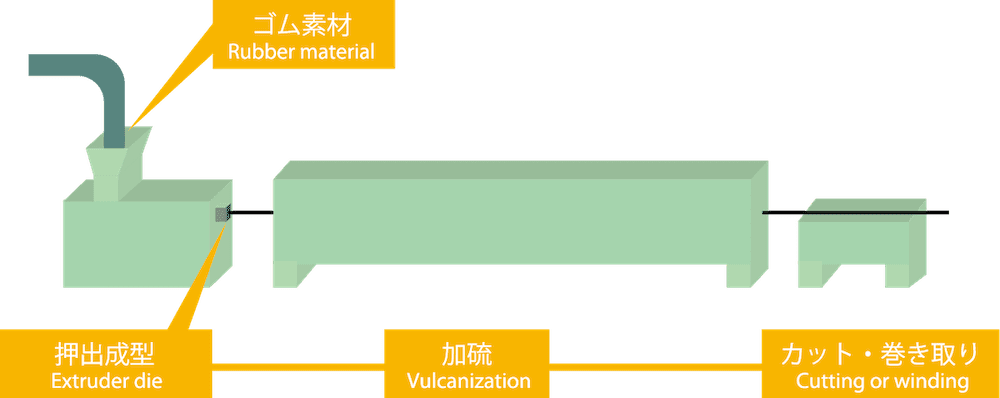

RUBBER EXTRUSION METHOD

Extrusion is one of the methods to form rubber into a desired uniform cross-sectional shape and size by extruding rubber through a die.

We are capable of manufacturing products of stable quality and good cost performance by continuous high-speed operation.

Feeding rubber material

Extrusion

Cutting

Winding

Rubber material is fed into a rubber extruder through the feed hopper. The material is plasticized with a rotating screw and pushed through a die, and then the extruded profile is vulcanized by heat. A chemical reaction between rubber and sulfur causes cross-linking of the polymer chains; it increases physical properties.

Plastic Extrusion Equipment

| Equipment | Number |

|---|---|

| 90mm Extruder | 3 |

| 60mm Extruder | 2 |

| 50mm Extruder | 1 |

| 40mm Extruder | 1 |

Vulcanizing System

| Equipment | Number |

|---|---|

| UHF Continuous Vulcanizing System | 3Set |

| Hot Air Dryer | 5 |

Other

| Equipment | Number |

|---|---|

| Winder Machine | 1 |

| Cutting Machine | 1 |

| Bonding Machine | 1 |

| Holing Machine | 1 |

| Electric Discharge Machine | 1 |

| Joint Processing Press Machine | 14 |

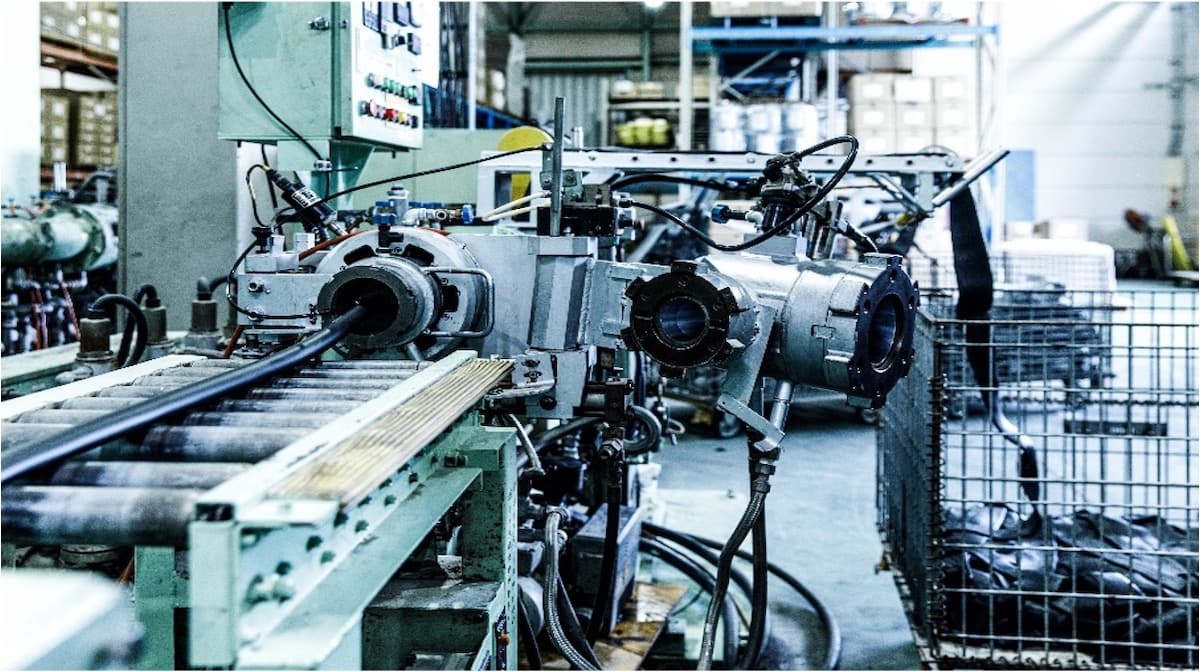

Factory

Extruder

UHF Continuous Vulcanizing System

Press molding machine for endless joint

Plastic Extrusion Equipment

Manufacturing and processing equipment list

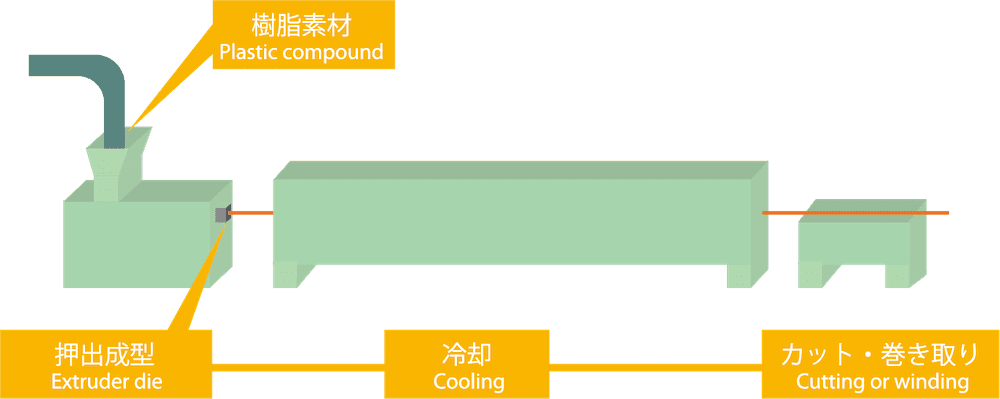

PLASTIC EXTRUSION METHOD

Extruded products are formed of various symthetic resin materials (pellets or powder). Plastic compound is supplied from the hopper of the extruder, and get melted and mixed in a heated cylinder. The liquefied plastic is continuously forced out through a die by driving screws to create a final form.

Then, extrusion profile is chilled with cold water flows, and solidified into a finished product.

We can manufacture precise products having a complicated shape, such as profile extrusions, tubings and so on.

Feading plastic compound

Extrusion

Cooling

Winding

Plastic Extrusion Equipment

| Equipment | Number |

|---|---|

| 90mm Extruder for prifile extrusion | 1 |

| 50mm Extruder for profile extrusion | 1 |

| 40mm Extruder for multilayer extrusion | 2 |

| 65mm Extruder for tube extrusion | 2 |

| 50mm Extruder for profile extrusion | 1 |

| 65mm Extruder for soft resin extrusion | 1 |

| 65mm Extruder for hard resin extrusion | 1 |

Irregular Extrusion

| Equipment | Number |

|---|---|

| Cooling Cistern | 5 |

| Winding Machine | 4 |

| Cutting Machine (Shear Blade, Rotary Type) | 4 |

| Winder Machine | 2 |

Hose Forming

| Equipment | Number |

|---|---|

| Gear Pump | 1 |

| Vacuum Cisterm | 1 |

| Cooling Cistern | 1 |

| Winding Machine | 3 |

| Spiral Blader | 1 |

| Ventical Blader | 1 |

Other Equipment

| Equipment | Number |

|---|---|

| Crusher | 3 |

| Hot Wind Dryer | 3 |

| Dehumidifying Dryer | 3 |

| Injection Molding (for Test Piece Making) | 1 |

| Accumulator | 1 |

| Winder Machine | 1 |

| Cutting Machine | 1 |

Factory

Large Irregular Line

Small Irregular Line

Hose & Tubing Line

All Products

-

Rubber & Flake Lining

-

Rubber Hose

-

Rubber & Plastic Extrusion

-

Rubber Molding