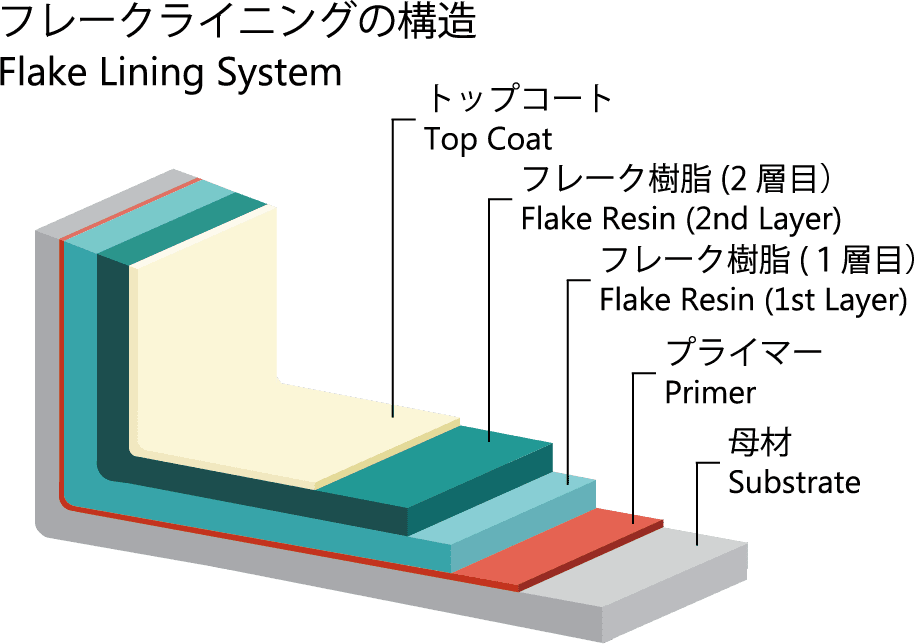

Flake Lining

Flake Lining is anti-corrosive coating systems for severe exposures.

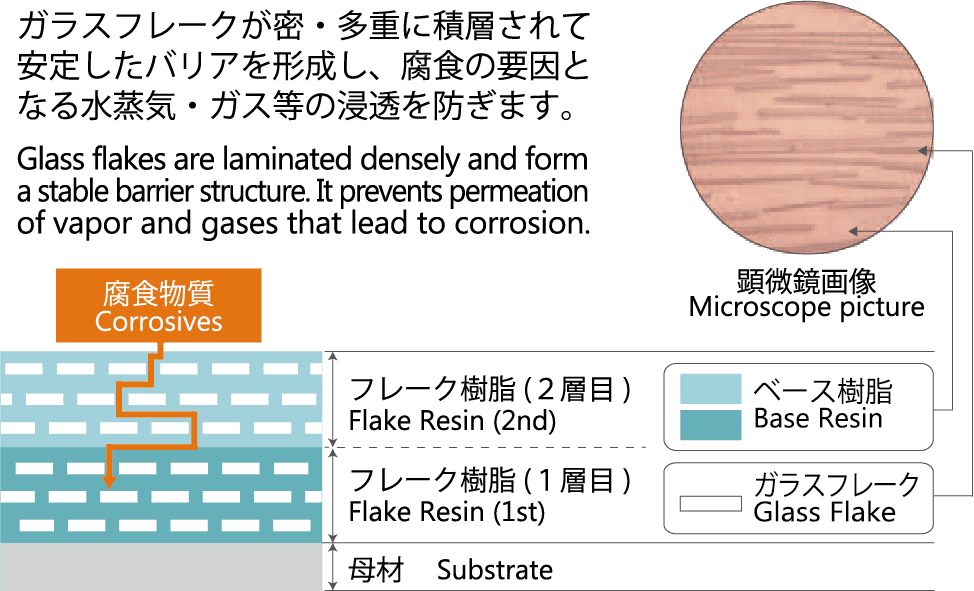

Flake compound is made from thermosetting liquid resin mixed with glass flakes in microns thick, and applied in a thickness of 0.5~3.0mm.

Glass flakes as barrier fillers make the coating much more durable and prevent permeability of corrosive substances, as the layers of laminated glass flakes (50~100 layers in 1mm thickness) form a highly impermeable structure.

- System

- Material

- Process

- Examples

Flake Lining System

Features and Advantage of Flake Lining

Features of Flake Resin

- Chemical Resistance

- Blister Resistance

- Heat Resistance

- Thermosetting

Advantage of Flake Lining

- Work Efficiency

- Excellent Bonding

- No Need to Cure

- Easy to Repair

Flake Lining Material

Heavy duty, Thick type

OHJI FLAKE 100 SERIES

- Thickness

- avg.2mm(2 coats)

- Method

- Trowel

Application

- FGD duct & tank

- Water treatment equipment

- Chemical tank

| Base Resin | Average Volume | Features | |

|---|---|---|---|

| HF-161 | Bis type Vinylester resin | 4kg/㎡ | Standard |

| HF-181 | Novolac type Vinylester resin | 4kg/㎡ | Heat Resistance |

Light duty, Thin type

OHJI FLAKE 200 & 300 SERIES

- Thickness

-

avg.0.8 mm(200 series)

avg.0.4 mm(300 series) - Method

- Spray or Roller

Application

- Oil tank

- Seawater pipe

- Ocean construction

OHJI FLAKE 200 SERIES

| Base Resin | Average Volume | Features | |

|---|---|---|---|

| HF-261 | Bis type Vinylester resin | 1.8kg/㎡ | standard 60℃-Liquid |

| HF-281 | Novolac type Vinylester resin | 1.8kg/㎡ | Heat resistance 150℃-Gas |

OHJI FLAKE 300 SERIES

| Base Resin | Average Volume | Features | |

|---|---|---|---|

| HF-361 | Bis type Vinylester resin | 1kg/㎡ | standard 55℃-Liquid |

| HF-381 | Novolac type Vinylester resin | 1kg/㎡ | Heat resistance 150℃-Gas |

Primer & Top coat

- Method

- Spray or Roller or Brush

OHJI PRIMER

| Base Resin | Average Volume | Features | |

|---|---|---|---|

| PR-60 | Bis type Vinylester resin | 0.2kg/㎡ | For metal surface |

| PR-90 | One component liquid type High-penetration Urethane Resin |

0.3kg/㎡ | For adhesion of different kinds of resin For concrete surface |

OHJI TOP COAT

| Base Resin | Average Volume | Features | |

|---|---|---|---|

| TC-60 | Bis type Vinylester resin | 0.3kg/㎡ | For smooth surface Easy cleaning |

| TC-80 | Novolac type Vinylester resin | 0.3kg/㎡ |

OHJI FLAKE

| Test Item | 100 series | 200 series | 300 series | |

| Bending Strength | MPa | 70 | 60 | 60 |

| Tensile Adhesive Shear Strength | MPa | 35 | 30 | 30 |

| Adhesion Strength | MPa | 13~16 | 13~16 | 13~16 |

| Flexural Modulus | MPa | 0.9x104 | 0.4x104 | 0.42x104 |

| Tensile Modulus | MPa | 1.0x105 | 5.3x103 | 5.3x103 |

| Tensile Elongation | % | 0.5 | 1.1 | 1.0 |

| Cure Shrinkage Rate | % | 0.1 | 0.15 | 0.15 |

| Vapor Permeability | g/24hrs·㎡· ㎜Hg/㎝ |

3.6x10-4 | 1.7x10-3 | 1.7x10-3 |

| Barcol Hardness | - | 40 | 40 | 40 |

| Taber Abrasion Coefficient | - | 40~50 | 40~50 | 40~50 |

| Linear Expansion Ratio | /℃ | 2.0~2.2x10-5 | 2.0~2.2x10-5 | 2.0~2.2x10-5 |

| Max. Working Temperature In liquid | ℃ | 100 | 54~60 | 49~55 |

| Max. Working Temperature In Gas | 150 | 150 | 150 |

- Surface Treatment

- Primer

Adhesive Coating - 1st

Flake Lining - 2nd

Flake Lining - Inspection

- Top Coat

All surface to be lined shall be grid or sand blasted to remove rust and spatter or old coatings completely from metal surface.

Blasted surfaces shall be coated with special primer for flake lining.

Flake resin patty is well mixed with proper quantity of hardener, and then applied with trowel or roller.

In general flake lining, 2 layers of glass flakes in each 1mm thickness to prevent involution of air and pinhole.

Any defects shall be found and repaired through pinhole, thickness and appearance inspection after hardening.

Top coat shall be applied.

(Not necessary for 200 & 300 series)

Examples of Flake Lining Application

Flue Gas Desulphurization (FGD) plant at Thermal power station

FGD Absorber and Duct

Concrete tank

Chemical tank

Waste water treatment tank

Chemical plant equipment

All Products

-

Rubber & Flake Lining

-

Rubber Hose

-

Rubber & Plastic Extrusion

-

Rubber Molding