Rubber Lining

OHJI Lining technologies have been making progress for over 50 years since our establishment.

OHJI have gained the top share in Japan, and also "OHJI" brand is well established overseas.

We will expand our business aggressively, being proud of our role as top maker in rubber lining industry.

- Process

- Examples

- Material

- Overseas

- Equipment

Process

OHJI rubber lining achieve high-level and stable quality by our skillful technicians who have inherited our technical know-how.

- Surface Treatment

- Primer

Adhesive Coating - Lining

- Curing

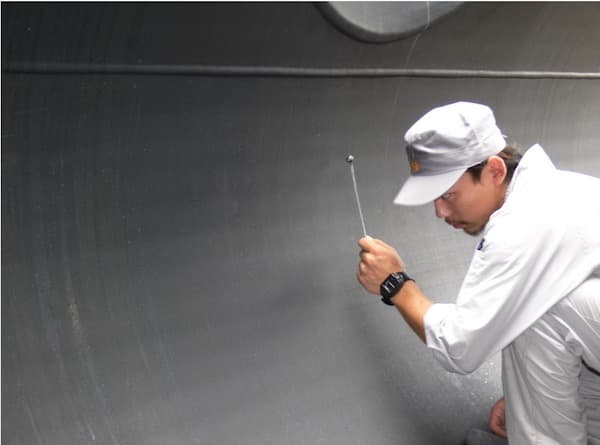

- Inspection

- Painting

Shipping

All surfaces to be lined shall be grid or sand blasted to remove rust and spatter or old coatings completely from metal surface.

Blasted surfaces shall be coated with special primer for rubber lining.

Appropriate rubber cement (adhesive) bonding shall be applied.

Rubber sheet cut into the suitable size shall be firmly bonded to the substrate with hand roller to eliminate air pockets between the rubber and the substrate.

Autoclave curing shall be carried out with pressured steam for shop lining.

Open steam curing at atmospheric pressure in case of on-site application.

Any defects shall be found and repaired through pinhole, hardness, thickness and appearance inspection.

Equipment shall be external painted according to customerts requirements.

Packing to avoid any damage during shipping.

Examples of Rubber Lining Application

It is said that the first natural rubber lining for industrial corrosion resistance has begun in Europe in the 1920s.

Now, rubber lining shows remarkable development thanks to the progress of synthetic rubber and adhesives. It is well known throughout all industries that have problems of corrosion and abrasion, and it is successfully adopted as the one of the most efficient way to prevent corrosion.

Inorganic Chemical Industry, Chemical Fertilizer Industry

Hydrochloric Acid Tank

Dichlorination tower

Pollution Control Equipment

FGD Equipment

Absorber circulation pipe

Field Rubber Lning for Huge Equipment

Hydrochloric acid (HCl) and caustic soda (NaOH) storage tank

Phosphoric acid plant

Tank for Conveying Corrosive Chemicals

Tank Lorry

Tanker

Steel Industry, Non-ferous Refining Industry

Pickling Tank

Thickener Rake

Other

Water treatment tank

Pump Casing

Rubber Sheet

The Roller Head Extruder forms the rubber compound into beautiful rubber sheets which feature a smooth surface, uniform thickness and without any air inclusions.

One of the most distinctive feature of the roller head unit is high performance. It provides a stable supply of high quality rubber sheets with good resistance to corrosion and wear.

We manufacture all processes from designing of mixture, kneading to sheeting.

Rubber Lining Material

OHJI's rubber lining materials are used for a wide variety of applications. Our experienced technical staff shall select the material which will be best suited for your needs.

Chracteristics of Rubber Materials

◎:Excellent ○:Good △:Not Good ×:Bad

| Natural Hard Rubber | Natural Soft Rubber | Butyl Rubber | Chloroprene Rubber | |

|---|---|---|---|---|

| Weather Resistance | ◎ | △ | ◎ | ◎ |

| Heat Resistance | ○ | △ | ○ | ○ |

| Acid Resistance | ◎ | △ | ◎ | ○ |

| Alkali Resistance | ◎ | ◎ | ◎ | ◎ |

| Abrasion Resistance | × | ◎ | △ | ◎ |

| Vapor Permeability | ◎ | △ | ◎ | ○ |

- Natural Hard Rubber

- Natural Soft Rubber

- Chloroprene Rubbe

- Butyl Rubber

- Other

| OHJI-HARD | Characteristics | General Application | Field Lining |

|---|---|---|---|

| E-5 |

Hard rubber used for chemical resistance under high temperature condition. Less flexible than E-7. |

Electrolytic equipment Recovery system for hydrochloric acid and alcohol Bromine production equipment |

- |

| E-5I | Compound of low Ca and Mg. | Special for Cell-Liquor of IM electrolysis | - |

| E-7 STANDARD |

Wide range of corrosion resistance. Excellent flexibility. Standard grade of natural hard rubber. Certified as water supply standard. (JWWA Z108-2004) |

Hydrochloric acid, Dilute sulfuric acid, Phosphoric acid, Caustic soda, etc. | - |

| E-7I | Compound of low Ca and Mg. |

IM electrolysis Used for the case of disrelishing metal ion |

- |

| E-8 | Used for oxide and osmotic agent, such as gaseous chlorine. | For equipment for gaseous chlorine (wet) of electrolysis in saturated | - |

| E-15 | General hard rubber for site application. |

Used when the organic solvent such as SO2 is mixed Same as E-7 |

○ |

| E-20 |

Hard rubber for site application. Compound of low Ca and Mg. |

Same as E-7I | ○ |

| OHJI-SOFT | Characteristics | General Application | Field Lining |

|---|---|---|---|

| R-4 | Used in the case of extreme slurry abrasion where R-6 is not sufficient. | For abrasion resistance of slurry | ○ |

| R-5 | Inadequate for slurry abrasion, but applicable for abrasion with large diameter of coarse particle and high loading | For special abrasion resistance | ○ |

| R-6 (R-16) STANDARD |

Standard grade of natural soft rubber for acid resistance. Alkali-resistance and slurry abrasion resistance shall be separately considered. |

Storage and piping for chemical resistance Suitable for caustic soda |

- |

| R-8 | Soft rubber blended with hard rubber for vulcanization. |

Used as SH type (SH-8078) |

○ |

| R-8I | Compound of low Ca and Mg. | Same as R-6 and R-8 | ○ |

| OHJI-PRENE | Characteristics | General Application | Field Lining |

|---|---|---|---|

| C-6 STANDARD |

Standard grade of CR. Except oxidizing chemicals of chemical resistance, heat and oil resistance, also excellent in ozone resistance. Can be applied for coexistent with hydrofluoric acid such as phosphoric acid production |

Phosphoric acid producting related equipment Seawater pipe Water box condenser |

○ |

| C-55 |

Self vulcanization type of CR. Vulcanization with operating temperature. |

NaOH storage, PAC, CaCl2 Wastewater treatment equipment | ○ |

| C-55F | Food grade of self vulcanization type of CR | Storage tanks for NaOH as a food additive | ○ |

| OHJI-AI | Characteristics | General Application | Field Lining |

|---|---|---|---|

| B-5(B-15) STANDARD |

Standard grade of butyl rubber. The most chemical resistant rubber. Excellent in vapor permeability among the natural rubber. Certified as water supply standard. (JWWA Z108:2004). |

Excellent resistance to H2SO4 and HF FGD equipment Phosphoric acid plant Nickel plant | ○ |

| B-5B(B-15B) |

Halogenated (bromo) butyl rubber. Same performance as B-5 (B-15). |

FGD system in overseas Phosphoric acid, nickel plant | ○ |

| B-55B |

Self vulcanization type of butyl rubber. Vulcanization with operating temperature. |

FGD system in overseas | ○ |

| B-5C(B-15C) |

Halogenated (chlorinated) butyl rubber. Same performance as B-5 (B-15). |

FGD system in overseas | ○ |

| B-5S |

Pre-cured type bromo butyl rubber. Not necessary for vulcanization. |

Large size tank for field For repair at FGD system |

○ |

| B-5BS |

Pre-cured type bromo butyl rubber. Not necessary for vulcanization. |

Large size tank for field For repair at FGD system |

○ |

| B-17 | Butyl rubber for NaCIO (Black). | Storage and piping of hypo-chlorite soda | ○ |

| B-115 | Non contamination grade for phosphoric acid. | High quality phosphoric acid storage | - |

- SH Type

- Characteristics

- SH-8078

SH-76 -

Although soft rubber type (R,C,B and S type) is not be damaged by shock or vibration, there is a problem in this point for hard rubber type (E type). When hard rubber is used for corrosion resistance and shock and vibration resistance need to be taken advantage, triple layer application or soft~hard~soft (SH type) is used.

SH (Sunhard) specifies the sign of each structure (hard~soft and soft~hard~soft) from metal surface, and the contents of thickness and material differs depending on the required service condition.

In this case, therefore, it is separately specified. Designed value of standard hardness differs from by each rubber structure .

OHJI aim to provide our services of quality and technology for global supply chain, which is enabled by not only OHJI 100% subsidiaries (China & Thailand) but also OHJI licensed business partners covering in the Asia overseas projects.

Overseas

Lining works at overseas partner companies

OHJI supply technical support and services to enable the same level of products as those installed in Japan with overseas local partners.

Please feel free to contact us for any your lining projects in your country and overseas.

Indonesia

Vietnam

Malaysia

Philippines

Rubber and Resin Lining Equipment

Manufacturing and processing equipment list

| Equipment | Number |

|---|---|

| Rubber Lining Factory | 1,500㎡ |

| Storage Yard | 6,000㎡ |

| Grid Blast Workshop | 100㎡ |

| Sand Blast Workshop | 260㎡ |

| Painting yard | 330㎡ |

| Large-Sized Vulcanizing Autoclave (4,000ø x 15,000L) | 1 |

| Middle-Sized Vulcanizing Autoclave (2,500ø x 5,500L) | 1 |

| Other Vulcanizing Autoclave | 3 |

| Gate Type Hoist Crane (5TON x 2) | 1 |

| Ceiling Hoist Crane (10TON) | 2 |

| Ceiling Hoist Crane (5TON) | 1 |

| Forklift Truck | 4 |

| Air Compressor | 5 |

| Truck for Field Lining | 2 |

| Boiler (Portable bolier for site 1.0 ton/hr) | 1 |

| Boiler (Portable bolier for site 0.3 ton/hr) | 1 |

| Boiler (Portable bolier for site 0.7 ton/hr) | 1 |

All Products

-

Rubber & Flake Lining

-

Rubber Hose

-

Rubber & Plastic Extrusion

-

Rubber Molding